How to create a central extraction system?

- Erol Köksoy

- Aug 5, 2025

- 4 min read

Updated: Sep 12, 2025

This question is frequently asked in consulting sessions. To clarify, we need to take a closer look at the functions and application options of a centralized extraction system. To determine whether a centralized extraction/centralized filtration system is the right solution for industrial ventilation systems, the components must be examined in detail.

FIXED INSTALLATION SUCTION SYSTEM COMPONENTS

Optimum selection and design of system components for the specific application and the best possible coordination of components result in a powerful suction system. In addition to specific application conditions, applicable regulations and guidelines must be taken into account when designing the suction system.

An extraction system normally consists of the following components:

FILTER UNIT:

The filter unit is the core of an extraction system. The better the design and function of the filter unit, the better the separation results. For example, the purer the air after filtration, the better.

The filter unit consists of filter media or filter elements installed in the filter housing. Depending on the application, filter bags, filter cartridges, or filter cassettes are used as filter elements in dry separation, while a water bath is used in wet filtration.

In dry separation, filter elements are generally cleanable. This ensures constant suction performance and low operating costs. To ensure effective separation, the number and design of filter elements must be appropriate for the media to be removed. To prevent filter clogging, the filter surface load (the ratio of filter area to the volume of air drawn in per hour) must not exceed a defined limit.

Another important factor is the ingress of dusty air into the filter housing. Air should flow as evenly as possible over the filter elements while maintaining a low upward flow rate through the filter unit. This allows the filter elements to be effectively cleaned during suction.

As a general rule, the higher the quality of the filter material, the lower the flow rate and filter surface load in the filter unit, and the more precise the filter cleaning, the better the filter performance and longer its service life. In practice, this translates to lower operating costs for the user.

VACUUM GENERATOR (FAN):

The vacuum generator of a central suction system provides the required air volume flow. A distinction is generally made between low vacuum generators, medium vacuum generators, and high vacuum generators. Medium and high vacuum generators are particularly important for dust extraction systems. Medium vacuum generators are generally fans used in applications where dust-containing air needs to be collected and removed. The negative pressure is approximately 8,000 Pa for medium to high air volumes. High vacuum generators include side-channel compressors and rotary piston or screw compressors. They are used in applications where accumulated material needs to be "picked up" and transported through high-resistance pipelines. The negative pressure is high (from 140 mbar onwards) and the air flow is relatively small.

To achieve satisfactory suction results, it is important to select the appropriate vacuum generator and design it according to the specific application requirements. Important factors include, for example, the number and simultaneity of suction points, the connection diameter at the suction points, the required conveying speed of the material to be vacuumed, and the length of the suction lines.

The vacuum generator is typically located next to the filter unit. Due to increasing demands for low noise emissions, vacuum generators are installed in enclosures that reduce operating noise while also providing weather protection in an outdoor environment.

DUST DISCHARGE:

The dust discharge is located in a central exhaust system directly below the filter unit and transports particles separated from the airflow through the filter unit. Collection bins, drums, or drawers connected to the filter unit by a cone are standard. It is important that the collection container volume is sufficient for the dust generated. If the collection containers are too small, emptying is often neglected, and the separated debris accumulates in the filter unit, resulting in poor performance.

For hazardous materials, low-dust disposal of the separated dirt is required.

For large dirt accumulations, automatic discharge elements such as rotary valves or discharge flaps that continuously convey the material through the filter unit are recommended.

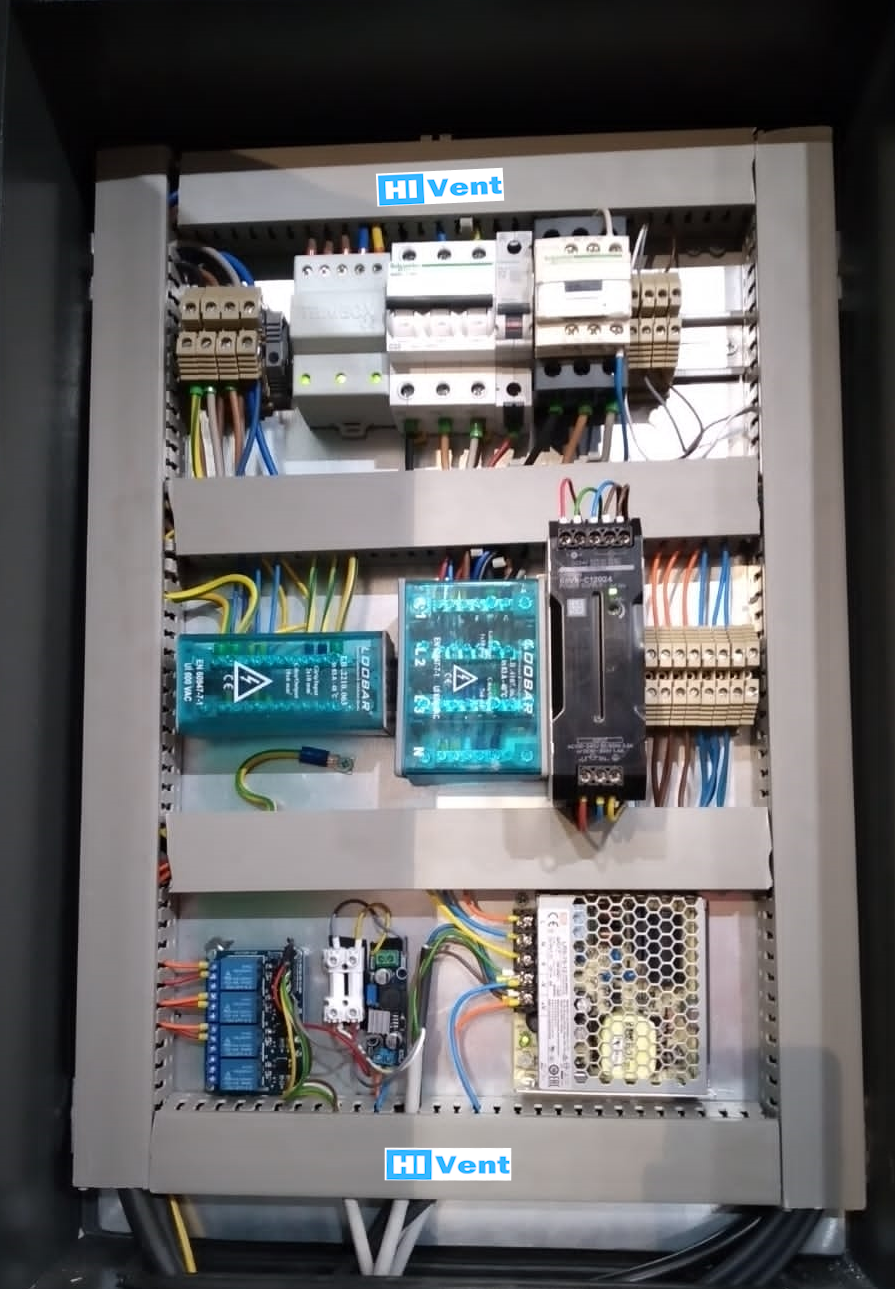

CONTROL UNIT:

The control unit – often referred to as the control cabinet – controls all the key functions of the central extraction system and ensures error-free operation. Numerous sensors now allow continuous monitoring of the most important system functions, enabling the system to operate almost completely automatically. For example, the extraction performance can be adjusted according to current requirements, based on the number of points to be extracted or the dust load in the airflow. This results in low operating costs thanks to low power and compressed air consumption. Outstanding maintenance or service work can now be determined based on performance data – not simply based on a fixed number of operating hours, as was the case in the past.

The control unit of the suction system, together with more powerful sensor technology and advanced software, makes it possible today (and above all in the future) to optimally adapt the system to the respective application.

OTHER COMPONENTS

In a broader sense, the following components also belong to a central suction system:

Suction pipe

Front separator

Heat recovery

Return/exhaust duct

For the satisfactory, long-term and economical operation of an extraction system, it is essential that the components are optimally adapted to each other and to the relevant application.

Comments