Welding fume extraction and filtration

- Erol Köksoy

- Aug 6, 2025

- 2 min read

Updated: Sep 12, 2025

Welding joins metal parts with intense heat, to which consumable electrodes are often applied to improve the assembly of larger parts. Smoke is emitted from the base metal and especially from the electrodes. Welding fume is a complex mixture of metals, gases and other compounds. It also contains very small particles, including ultrafine matter. The exposure of welders depends on several factors, including the welding process itself, workplace characteristics and protective measures.

Protect yourself from welding fumes!

Several hazards have been associated with exposure to welding fume particles.

These hazards are related to the high concentrations of aerosolised fine and ultrafine metal and metal oxide particles produced by the welding arc. The heat generated by the arc melts the electrode, which is transferred to the weld pool in the form of superheated metal droplets. Spatter particles are also formed. The spatter particles and heated metal droplets produce high concentrations of supersaturated metal vapours which then nucleate to form solid particles. As these particles cool to ambient temperatures they undergo condensation and coagulation, leading to the formation of chain aggregates and agglomerates.

Welders work in a multitude of environments, ranging from outdoor, open, well-ventilated areas (e.g. construction sites) to enclosed, poorly ventilated areas (e.g. crawl spaces, ship hulls and pipelines). The proximity of the welder to the arc exposes the operator to high concentrations of metal fumes); therefore, exposure studies often measure fume concentrations in the welder's breathing zone. In recent years, researchers have placed increasing emphasis on studying the effects of exposure to certain fume components, such as manganese, chromium, nickel and other volatile chemical species, and looking for ways to minimise exposure.

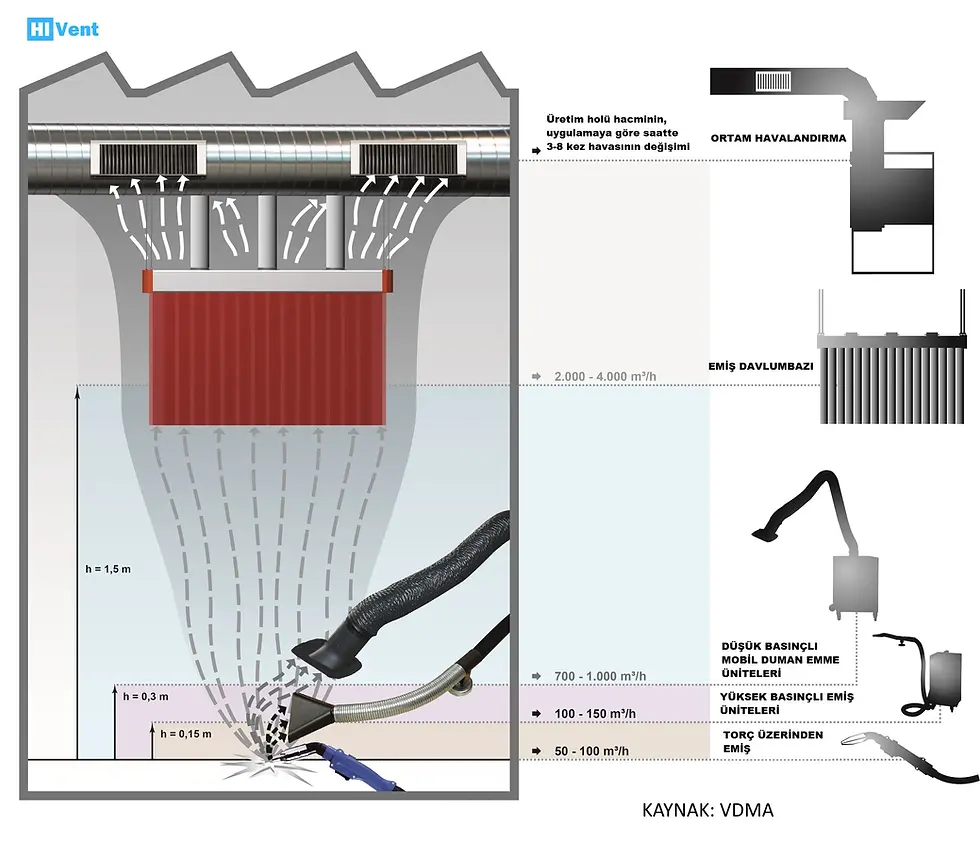

A great deal of effort has also gone into the development of welding shop ventilation systems to remove welding fumes. Some of these ventilation systems include fume extraction torches, localised fume extractors, welding booths with built-in extraction walls, filter tower and hall ventilation systems. Despite these options, for practical or economic reasons, welding operations often occur in open areas without engineering controls, where nearby workers engaged in other tasks may also be exposed to fumes. This can be particularly common in construction or manufacturing facilities where workers at multiple stations share the same large, open work area. In general, although efforts are made to shield the arc and protect nearby workers from exposure to ultraviolet light, little is usually done to control and prevent exposure from fumes. This results in not only exposure of the welder to welding fumes, but also second-hand exposure of nearby workers.

Comments